Search This Supplers Products:Steel structureRivet welding processingCNC machiningequipment installationpipeline constructionCoating waterproof

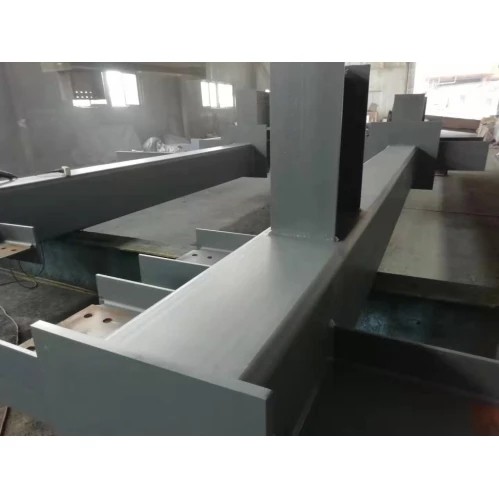

Steel structure manufacturing process

time2020/01/06

- The steel structure production process includes the following.

1. Staking out and numbering materials Staking out is the first procedure in the manufacturing process of steel structures. Only when the staking out size is accurate can the accumulated errors in subsequent processing steps be avoided and the quality of the entire component can be guaranteed.

Second, cutting The cutting methods of steel material cutting are cutting, punching, sawing, gas cutting, etc. Which method to use in construction should be determined according to specific requirements and actual conditions. After cutting, there must be no delamination and no cracks on the section.

Correction and shaping

1. Correction: In the process of manufacturing steel structures, due to the existence of raw material deformation, cutting deformation, welding deformation, and transportation deformation, the production and installation of components will be affected. Correction is to cause new deformation to offset the deformation that has occurred.

2. Bending forming: The cold bending forming methods include rounding machine rolling, press bending, top bending, and drawing bending. Fourth, edge processing In the manufacture of steel structures, the internal structure of the edge of the steel plate after shearing or gas cutting will change. In order to ensure the quality of important components such as steel beams or heavy crane beams, the edges need to be machined. V. Making holes There are usually two methods of making holes: drilling and punching. Drilling is a commonly used method in the manufacture of steel structures;

Six, assembly Assembly, also known as assembly, assembly, is assembled according to the requirements of the construction drawings into a single component.

Seven, welding construction Welding is one of the most important connection methods used in steel structures.

Eight, high-strength bolted connection construction High-strength bolted connection is one of the main connection methods of steel structures that are juxtaposed with welding.It is characterized by convenient construction, removable and replaceable, uniform force transmission, good joint rigidity, large bearing capacity, and fatigue resistance. High strength, nuts are not easy to loose, and the structure is safe and reliable.

Dalian Guangtong Steel Structure Co., Ltd. is a company specializing in the design and manufacture of steel structures and non-standard metal components. It has dozens of advanced processing and testing equipment. Company leaders and employees always put product quality first and insist "High standard, zero defect" production quality concept, sincere heart to provide customers with the most sincere service. Quality is not only the quality of the product, but also the persistence and soul of Guangtong Steel Structure. Guangtong Steel Structure practises corporate production responsibility and social responsibility, and integrates the "quality view" into all products manufactured. Strict production standards and quality control cast the ultimate quality of Guangtong's steel products.