Search This Supplers Products:Steel structureRivet welding processingCNC machiningequipment installationpipeline constructionCoating waterproof

CNC cutting, welding steel plate production of metal components and steel structure construction.

- FOB Price

US $1260.001 - 100 metric ton

US $1170.00101 - 1,000 metric ton

- group name

- Steel structure parts

- Min Order

- 1 metric ton

- brand name

- FXGTSS

- model

- GTG-W42

- Nearest port for product export

- Dalian, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash

- update time

- Tue, 23 Feb 2021 13:24:57 GMT

Paramtents

Material Q355B

Brand FXGTSS

Packging & Delivery

-

Min Order1 metric ton

Briefing

The steel plate is cut by numerical control method and then made by welding method.

Detailed

|

Product name

|

CNC cutting and welding steel plate

|

||

|

Brand

|

Dalian Guangtong Steel Structure Co., Ltd. FXGTSS

|

||

|

Material

|

Q355B

|

||

|

Specification (weight / span, height)

|

1099.7t/36m,13m / Customized

|

||

Roof load value | 1.0KN/m² | ||

Shockproof strength | Level 7 | ||

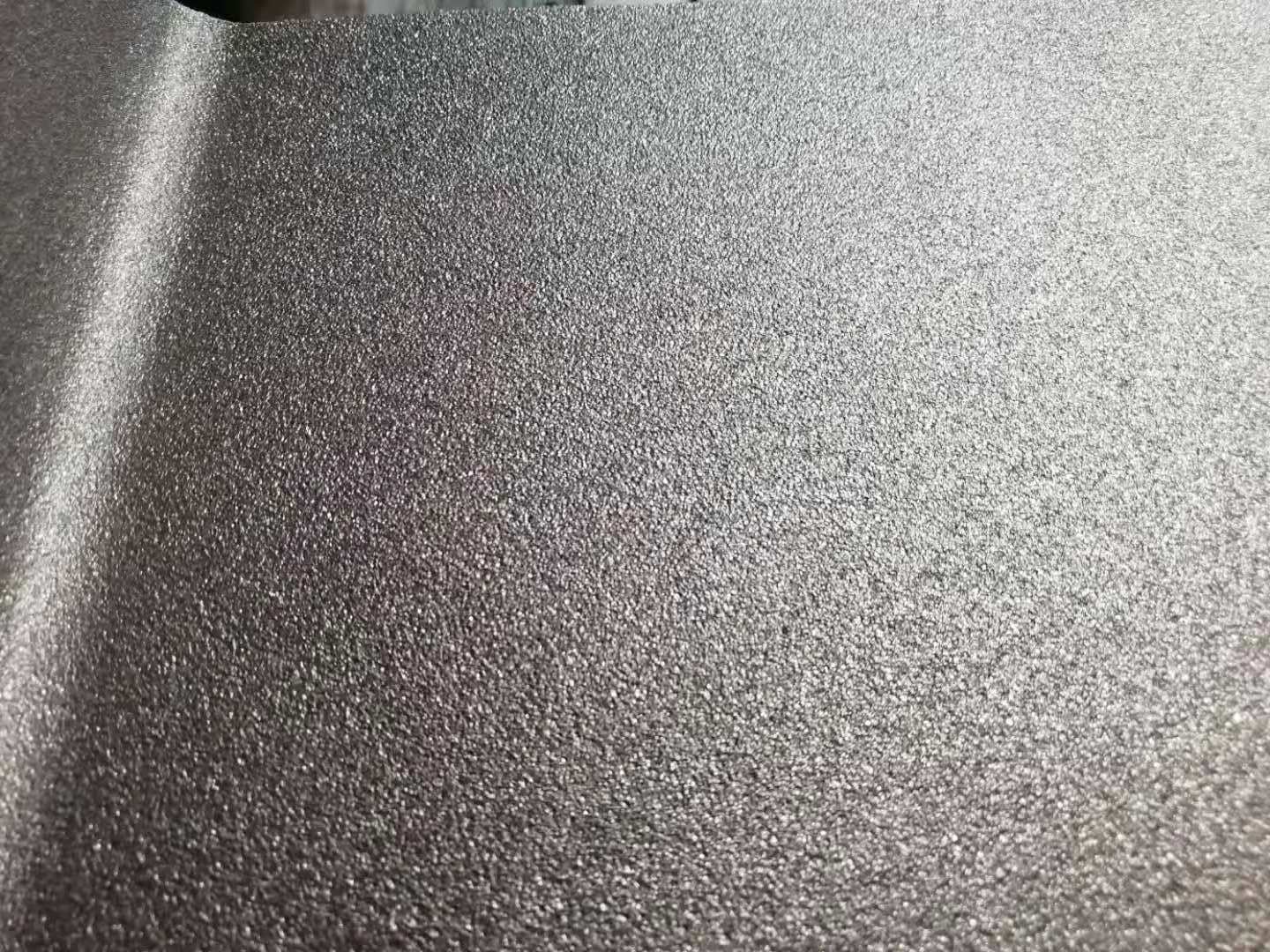

Surface treatment | Sand blasting and derusting grade sad3 | ||

Anti corrosion treatment | Epoxy zinc rich primer, polyurethane finish | ||

Coating thickness | >65 μm, >100 μm | ||

Use | CNC cutting and welding steel plate can be used in mechanical manufacturing, pressure vessel, structural pipe manufacturing, architectural decoration, chemical equipment, elevator, rail transit, etc. | ||

Feature | 1. 1. CNC cutting steel plate has high strength and rigidity, good compression and seismic performance 2. High temperature and corrosion resistance, durable. 3. The surface is cut smooth, beautiful and free of burrs. 4. It is green, pollution-free and recyclable. | ||

Installation method | On site hoisting assembly, bolt connection and installation | ||

Delivery time | 10 tons: 15-20 days; 11-50 tons: 35-50 days | ||

Payment method | TT, T/T |

For steel structure parts with special requirements such as air tightness test, sand blasting, rust removal and paint anti-corrosion treatment must be carried out.

Before leaving the factory, steel structure parts need to be shot blasted for rust removal and coated with anti-corrosion paint.

The steel plate is cut into small pieces by numerical control method and then welded.

Because the workshop worker master's exquisite skill welding steel structure is more perfect.